Lathes and milling machines are used to cut raw material. In this machine, a workpiece is given a shape and converted into the desired shapes. Both of these machines follow a similar method called subtractive machining, but these machines greatly vary in usage and functionality. This article will give you extensive knowledge about the functional differences between these two machines individually, which is the most commonly asked question.

Lathe VS Mill

Following are some of the fundamental differences between the lathe and the milling machine:

Difference in Technique

Both of these machines use different techniques, which is the most significant difference. The material is spun by the lathe machine, whereas, in the milling machine, a tool is predominantly used to spin the material. On a lathe, the workpiece is in motion, while in the milling machine, the workpiece remains put.

Difference in Accuracy

A milling service machine permits its tools to reach the most complex parts of the workpiece, allowing more precision and accuracy. On the other hand, the lathe allows less accuracy comparatively, but if you want to produce fast and easy cylindrical parts, a lathe could help you out immensely. If you're going to generate parts in a mill, you will have to have proper tools.

Adaptability

A milling machine has more tools to help you cut more creative shapes. A lathe is not very versatile and very limited as it can only work for cylindrical parts. A lathe cannot create unique designs.

Type of Work

A milling machine can cut the workpiece from various angles, like making an off-center hole or straight cuts in the metal, but you can only drill in the center if you are using a lathe.

Tool Usage

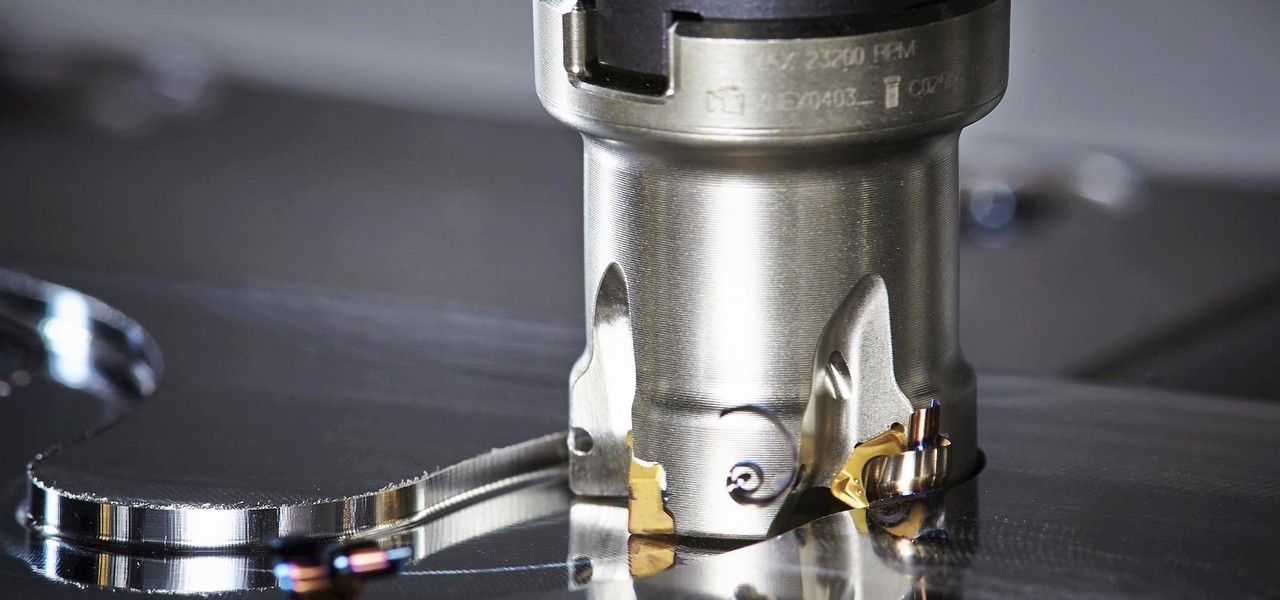

The tools used in CNC milling are end-mills, face-mills, and drills. All these tools are beneficial in producing unique and creative designs. On the other hand, the primary tool used by a lathe is an insert cutter which will prove a great help in creating cylindrical parts.

Functions

The milling machines can perform boring, shaping, rounding off edges, cutting, flattening. Contrastingly, lathe machines permit cutting, turning, sanding, and drilling.

Installation

Installation of milling machines is much easier than installing lathe machines. For installing a milling machine, you have to take measurements beforehand, and while installing, you have to make sure that it's straight. However, to set up a lathe, make sure that the chuck jaws that are installed should be equidistant from the center.

Computer numerical control (CNC)

An amazing fact about both machines is that they can be operated manually and from a computer. They can work efficiently with wood, plastics, and metal. With the developing technology, multitasking machines are also available.

Final verdict

After reading all the points above, which differentiate between a lathe and the mill, you can get a clear understanding of the different functions of both machines. This knowledge will help you get the maximum results out of both of them.